Cell line development – the process of establishing a cell clone that has been genetically engineered to produce high and consistent levels of a target therapeutic protein – is a complex and multi-stage process.

For our industry and academic partners focused on accelerating the translation of research into the clinic and tackling potential pitfalls before they arise, selecting a high quality, consistent gelatin that is designed to support the survival and performance of cells, such as X-PURE®, can save time, cost and improve your chances of overcoming regulatory hurdles.

In this blog, we explain three ways in which gelatin can improve your cell line development workflow and optimize your protein yield.

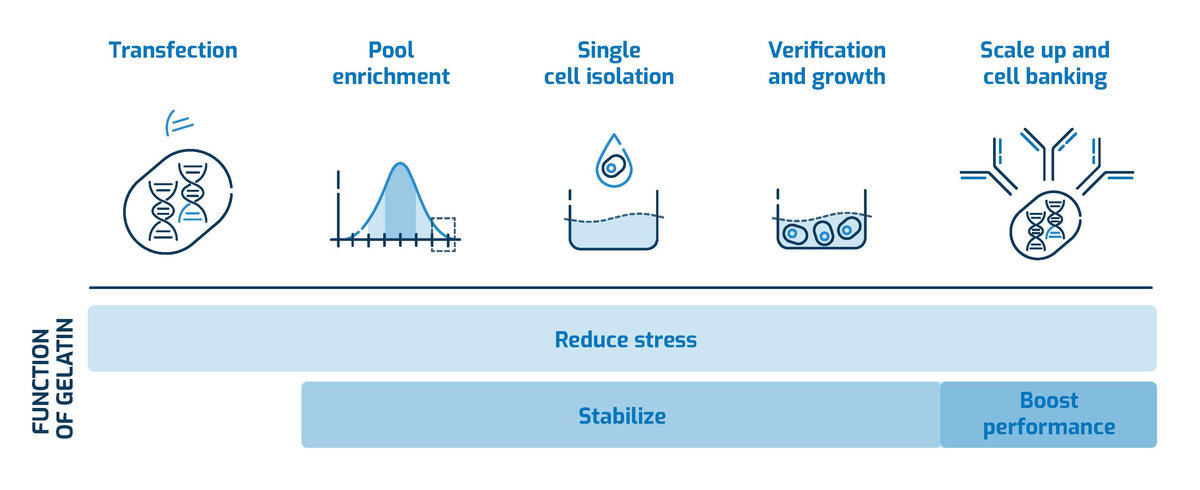

Figure 1: Gelatin can optimize every stage of the cell line development process by helping to reduce stress, improve stability and boost performance

1. Gelatin reduces cell stress

The cell line development process puts cells under a high level of stress, which can lead to extensive cell death, detachment, low transfection and low survival rates, especially for specific systems or cell types.

Gelatin is a natural biomaterial derived from collagen, the main structural element of the Extracellular matrix (ECM). Because it is collagen-derived, gelatin has a similar molecular structure and function to collagen thus mimicking the cell’s natural collagenous environment. Applying a gelatin coating such as X-Pure helps to recreate the cell’s natural environment and improve attachment of cells in culture. Reducing cell stress is important at every step of the cell line development, from transfection through to final scale up.

One crucial step in the whole procedure is single cell isolation and the impact of this on cellular communication, as many cells find it difficult to grow in the absence of other cells. For those cells, cell isolation using a hydrogel can be considered. X-Pure GelMA (gelatin methacryloyl) can be tailored to mimic the stiffness and porosity of a cell’s natural environment. This reduces stress while also allowing cells to communicate and exchange signals with other cells to aid growth and survival.

2. Gelatin enhances cell performance

Once clones have been identified, isolated and verified, the lead clones must be expanded and scaled up. At this stage, gelatin can help to further optimize cell culture conditions to improve cell performance and yield.

Many biological therapeutics are produced with mammalian cells in culture, such as Chinese Hamster Ovary (CHO) cells, human embryo kidney (HEK293) cells, or PER.C6 cells. These cells are cultured using either adherent cell culture, which requires attachment of cells to substrates, or suspension cell culture – where cells are suspended in agitated cell culture medium in a culture vessel.

The key challenges for adherent cell culture are low yields and high batch-to-batch variation. Choosing highly consistent gelatins that can be tailored to the cell type can help to overcome these problems.

The main challenge for suspension cell culture is that agitation puts cells under a substantial amount of hydrodynamic stress. Well-characterized and purified gelatins can help to provide an optimal 3D environment for cells and act as a physical barrier to prevent stress. Crosslinked gelatin hydrogels, such as GelMA or GelDAT (gelatin desaminotyrosine), are an ideal choice for this type of system because they are stable at body temperature and contain natural cell binding motifs.

3. Low-endotoxin gelatin improves cell stability

When choosing a biomaterial for cell line development, it is crucial to ensure that products are purified and traceable to reduce the risk of introducing contaminants, such as endotoxins or lipopolysaccharides (LPS). Endotoxins in gelatin can lead to altered cellular responses and misinterpretation of results, causing delays in research translation(1).

Rousselot’s X-Pure range offers highly purified pharmaceutical grade gelatins with extremely low endotoxin levels (< 10EU/g), consistent quality and traceability to the source, helping to ensure that your cell line development workflow is not held up by contaminants. X-Pure is also batch-to-batch consistent, helping you to minimize data variability and providing a stable environment where cells can thrive.

Research has shown that using high-purity gelatin products can help to boost cell proliferation; a recent study demonstrated that Rousselot’s ultra-pure GMP-grade gelatins outperformed standard non-endotoxin purified research grade gelatins and other coating materials in 2D cell culturing.

X-Pure gelatin can improve your cell line development workflow

X-Pure gelatin is an ideal, adjustable and versatile mimic of the extracellular matrix which creates a perfect environment to support your cells throughout the entire cell line development process. By helping to reduce cellular stress, improve stability and boost performance, X-Pure can help researchers and therapeutic protein manufactures to improve protein yields. X-Pure’s batch-to-batch consistency, traceability and regulatory compliance can help to accelerate the delivery of treatments to patients.

References

(1) Heinrich, M.A., M. Mangia, and J. Prakash, Impact of endotoxins on bioengineered tissues and models. Trends Biotechnol, 2021.