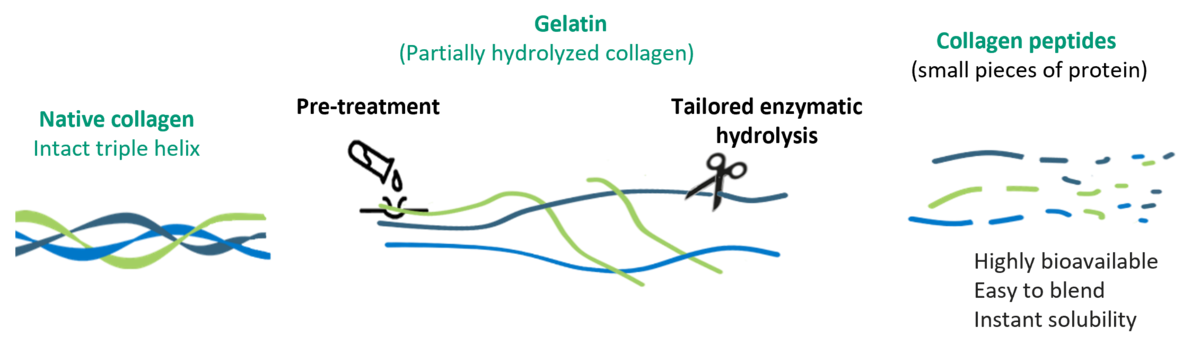

Peptan® is backed by science, with peer-reviewed scientific articles demonstrating that it delivers holistic benefits, making it a solution for beauty, an active lifestyle, and healthy aging (source: https://peptan.com/what-is-peptan)

Figure 1: Cleavage of collagen into bioactive collagen peptides (Peptan)

Peptan in heat-treated beverages

1. Impact of heat treatment on drinks with Peptan

For long-term stability, heat treatments such as pasteurization and Ultra-high temperature (UHT) treatment are commonly applied to commercially available drinks. With Peptan, these heat treatments do not significantly impact the color or clarity of drinks, both in neutral and acidic conditions, as shown in Figure 2 on lab-scale formulated samples.

Similarly, on industrial scale, drinks with Peptan were heat-treated using a UHT steam injection equipment (142°C, 6s). There was no difference observed in the drink before and after the UHT, as shown in Figure 3.

Figure 2: 10%w/w Peptan solutions: pH 6.5 and pH 3.5 (right)

Figure 3: Peach-flavored RTD with Peptan (7%), citric acids, sweetener: sample of drink before heat treatment (left) and after UHT treatment (right)

Source: Internal Rousselot study, Global Application Center, 2023

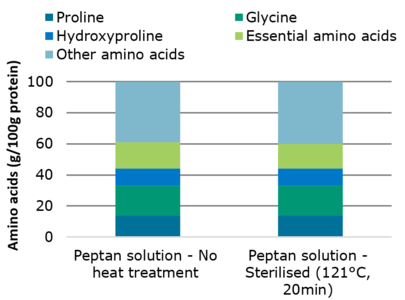

2. Peptan's stability in heat-treated drinks

Peptan does not break down at the high temperatures used in the food industry.

When non-heated Peptan solutions and sterilized solutions (121°C for 20minutes), both at 10% (w/w), were analyzed using HPLC, the results showed that amino acid composition of both solutions remain unchanged, even under the high processing temperatures used in the food industry (Figure 4).

Figure 4: Amino acid composition of Peptan solutions before and after heat treatment

Source: Internal Rousselot study, Global Application Center, 2024

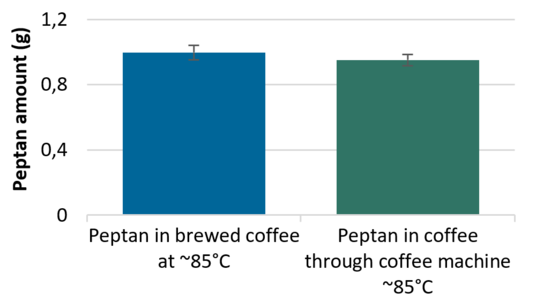

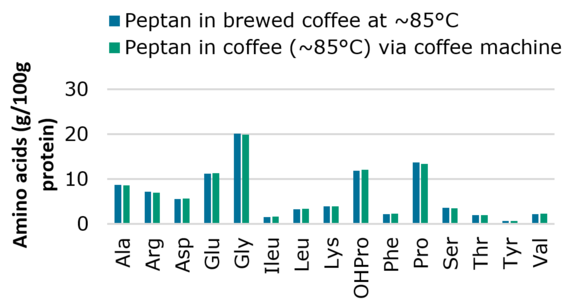

3. Case study of Peptan in hot coffee

A study was conducted to evaluate if Peptan fully dissolves when passed through a coffee machine. One gram of Peptan was mixed with 1.8 grams of ground coffee and placed into refillable stainless steel capsules. The blend was brewed through a capsule coffee machine (~85°C, 19 bar pressure). In a separate cup, one gram of Peptan was manually dissolved in the same volume of already brewed coffee (~85°C). Both liquids were analyzed using HPLC, revealing no significant loss of Peptan. In addition, the amino acid composition did not change between the samples (see Figures 5 & 6 below).

Figure 5: Impact of coffee preparation: Peptan added to brewed coffee vs Peptan via coffee machine

Figure 6: Amino acid composition of Peptan in brewed coffee vs Peptan in coffee from coffee machine

Source: Internal Rousselot study, Global Application Center, 2024

What about the bioavailability of Peptan in hot coffee vs cold beverages?

A randomized, double-blind clinical trial (Poster from Virgilio et al., 2024) was conducted on healthy subjects. In this study, 10g of Peptan was added to 200ml of water at ambient temperature and to hot coffee (Brand: Nescafé GOLD Das Original, 60 – 80°C). The concentrations of the di-peptides Proline-Hydroxyproline (Pro-Hyp) and Hydroxyproline-Glycine (Hyp-Gly) in the blood after digestion were recorded at different intervals, as shown in Figures 7a & 7b. These are the two di-peptides to which most functionality of collagen has been attributed. The total absorption of Pro-Hyp and Hyp-Gly from Peptan in coffee and water was found to be statistically the same.

![Concentration-time curves of Proline -Hydroxyproline response [ng/mL] after intake of study products (n=6) Concentration-time curves of Proline -Hydroxyproline response [ng/mL] after intake of study products (n=6)](https://d1ip4j1950xau.cloudfront.net/_processed_/a/8/csm_Figure%207a_12ea807efb.png)

Figure 7a: Concentration-time curves of Proline -Hydroxyproline response [ng/mL] after intake of study products (n=6)

![Concentration-time curves of Hydroxyproline-Glycine response [ng/mL] after intake of study products (n=6) Concentration-time curves of Hydroxyproline-Glycine response [ng/mL] after intake of study products (n=6)](https://d1ip4j1950xau.cloudfront.net/_processed_/3/6/csm_figure%207b_7392b635b8.png)

Figure 7b: Concentration-time curves of Hydroxyproline-Glycine response [ng/mL] after intake of study products (n=6)

Source: Poster Virgilio et al., 2024

Peptan in baking

At Rousselot’s Global Application Center, many recipes have been developed for bakery applications with Peptan collagen peptides. From home-baking formulations to industrial processing, solutions have been created for optimal flavor, nutritional value, and shelf-life of the end-product (see Figure 8).

Figure 8: Examples of bakery products with Peptan

Peptan’s stability during baking

One study on heat stability of Peptan in bakery applications showed that Peptan is not broken down at high baking temperatures of 200°C, 20min. This includes a wide range of bakery applications, including muffins, pancakes, waffles, brownies, cookies, and more…

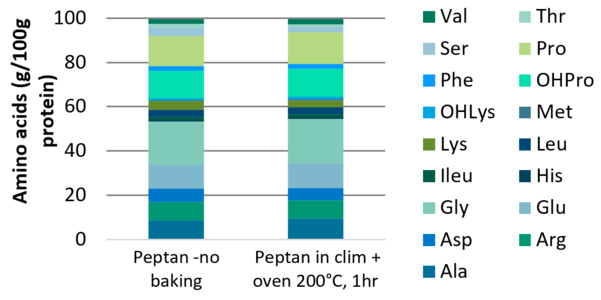

In a similar study, to simulate the effects longer baking times, samples were stored for 1 hour in a climatic chamber (clim) at 35°C and relative humidity 80% before being baked for 1 hour at 200°C. After baking, the samples were left to dry in desiccators and then analyzed using HPLC. It was found that the amino acid composition of the Peptan does not change (Figure 9 below).

Figure 9: Amino acid composition of Peptan before and after baking in oven at 200°C

Source: Internal Rousselot study, Global Application Center, 2024