“Microcarriers are finding success1 in the expanding cell culturing market2,” said Leonard van Bokhorst, CEO of IamFluidics. “They provide a larger surface for cell attachment than traditional flat (2D) cultures and facilitate scaling up from lab-scale to large-scale bioreactors for efficient commercial production. However, their non-solubility limits efficient cell harvesting. The new dissolvable microcarrier, developed with Rousselot, addresses this challenge.”

The dissolvable microcarrier is produced using IamFluidics’ patented IN-AIR MICROFLUIDICS™ technology. It consists of alginate-based microcarriers, coated with Rousselot’s denatured collagen, which comes with full documentation, including a virus-inactivation certificate. The

new microcarrier offers the following advantages:

- Enhanced cell attachment and growth: The denatured collagen promotes cell attachment and growth, similar to natural processes in the body, and supports physiological interactions between cells and the material. The dissolvable microcarriers are suitable for mesenchymal stem cells (MSCs) and other adherent cell lines.

- Rapid dissolution for efficient harvesting: The microcarriers dissolve within 15 minutes after the addition of standard cell culturing reagents, allowing for efficient cell harvesting and swift integration into existing cell-expansion systems.

- High-harvesting efficiency: With over 90% cell harvesting efficiency and viability, the dissolvable microcarriers dramatically reduce cell loss compared to the typical 50% seen with non-dissolvable microcarriers.

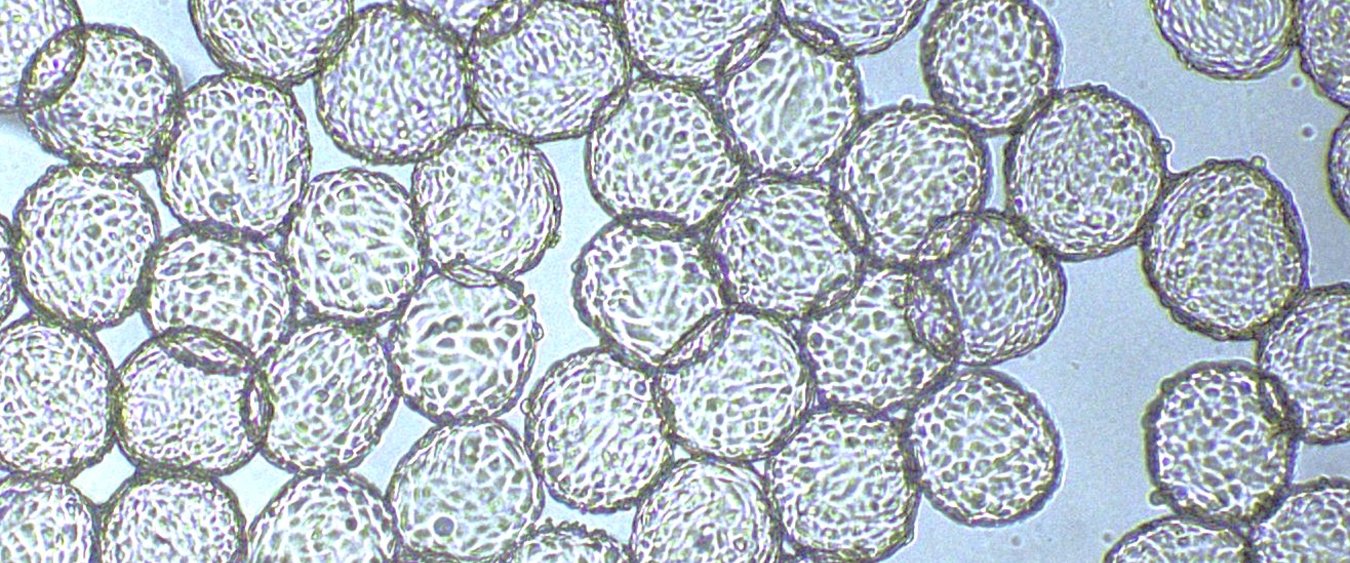

- Consistent and easy handling: The monodisperse and transparent microcarriers enable reproducible and easy handling, following standard cell culturing protocols.

Tanja Vervust, Global Director Biomedical at Rousselot said, "We are thrilled to collaborate with IamFluidics, whose exceptional expertise and speed of innovation set them apart. By combining our high-quality denatured collagen with their advanced technology, our new dissolvable microcarrier offers the consistency and quality essential for large-scale production. This breakthrough has the potential to accelerate clinical translation, a core focus of all our biomedical solutions.”

Van Bokhorst said, “The integration of our innovative IamFluidics’ technology with Rousselot’s unmatched collagen expertise represents a major step forward for the biopharmaceutical industry. This collaboration is set to transform adherent cell culture, offering high yield, costeffective,

scalable solutions for cell-based products and therapies.”

The dissolvable microcarriers are available online via the webshop microparticles.shop.

Technical background on microcarriers

Microcarriers are small particles that are used in various fields, including cell therapy and biotechnology. Essentially, microcarriers are tiny beads ranging in size from 100-300 microns. Microcarriers provide a larger surface area for cell attachment, allowing expansion capacity to be amplified several folds compared to traditional flat cultures. Instead of being cultivated on a flat surface, cells are cultured on spherical microcarriers that remain in suspension, with each microcarrier carrying numerous cells. The three-dimensional microcarrier system for cell culturing is applicable for a variety of fields, including regenerative medicine, cultivated meat and vaccine production.

1 Grandview research, Microcarriers Market Size & Trends, By End-use, By Region, And Segment Forecasts, 2025 - 2030

2 Grandview research, Cell Culture Market, Dynamics & Ecosystems, Global Forecast to 2029