To help patients suffering from tissue damage caused by disease or injury, 3D bioprinting technology has emerged as an excellent method to create 3D living constructs. Biomaterials such as gelatin can be combined with living cells and drugs to create bioinks that can be 3D bioprinted into functional tissues.

Traditional bioprinting approaches generally rely on large desktop bioprinters to create in vitro 3D living constructs before introducing them into the patient’s body. But this process has several drawbacks, including surface mismatches, structural damage, contamination and tissue injury caused by transport and surgery.

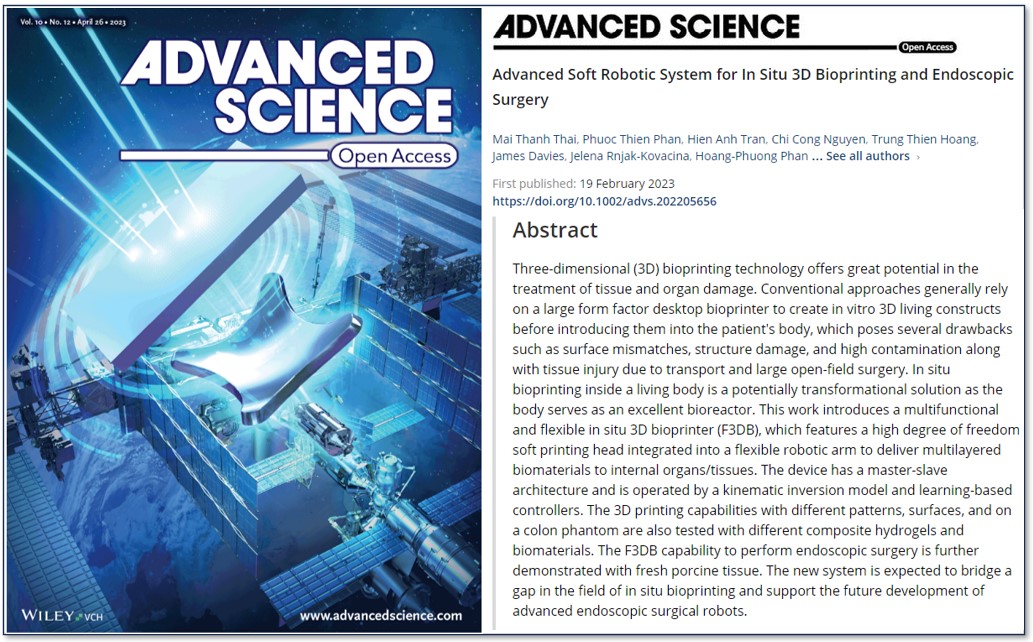

A potential solution is to use in situ bioprinting techniques to deliver the biomaterials directly to the damaged area. This is the focus of a recent study by Mai Thanh Thai and colleagues, published in Advanced Science, which introduces a new concept of a flexible 3D bioprinter where biomaterials can be directly delivered into the target tissue or organ with a minimally invasive approach.

“Using soft robotic technology, we have demonstrated the feasibility of a multifunctional and flexible robot (F3DB) that could perform both in-situ 3D bioprinting and endoscopic surgery. This new device is expected to bridge a major gap in in-situ bioprinting and endoscopic surgery”.

Dr Thanh Nho Do is currently a Scientia Senior Lecturer at Graduate School of Biomedical Engineering (GSBmE), University of New South Wales (UNSW), Sydney. He directs the UNSW Medical Robotics Lab.

The novel bioprinting system uses soft artificial muscles to control a 3D printing head, utilizing a machine learning based controller to provide accurate motion. The 3D printing capabilities were tested with a fresh porcine kidney and an artificial colon using various hydrogels and biomaterials, including X-Pure GelDAT.

Crucially, the adherence and ability of the 3D printed construct to interact with internal tissues and organs is greatly dependent on the biomaterials used. The use of pharmaceutical-grade X-Pure GelDAT was key to creating a perfect environment for cell growth, thanks to its ultra-low endotoxin levels and biocompatability. X-Pure GelDAT hydrogels are ideal for complex wound dressings due to their exceptional adhesive properties and ability to crosslink with tissues.

“We chose to use GelDAT in this work due to its ease of extrusion and photopolymerization, making it an excellent bioink platform to test this new device”

Dr Jelena Rnjak-Kovacina is a Scientia Associate Professor and ARC Future Fellow at the Graduate School of Biomedical Engineering.

As part of the study, the researchers examined the viability of the cells following the printing process, which involves the living biomaterial traveling through a long fluid transmission tube and through the printer nozzle. The results revealed that the cells were not affected by the printing process as the majority of cells were still alive post printing.

By combining the latest advanced robotics with premium biomaterials that can support cell growth and adherence, this study offers new hope for delivering biomaterials in situ for faster restoration and healing of damaged tissues and organs.

3 key features to check when selecting the best bio-ink for your 3D bioprinter